Multi-Material

3D Printing

Systems

+ Materials

What makes the

MMJ ProX Series special?

True Multi-Material 3D Printing in one build

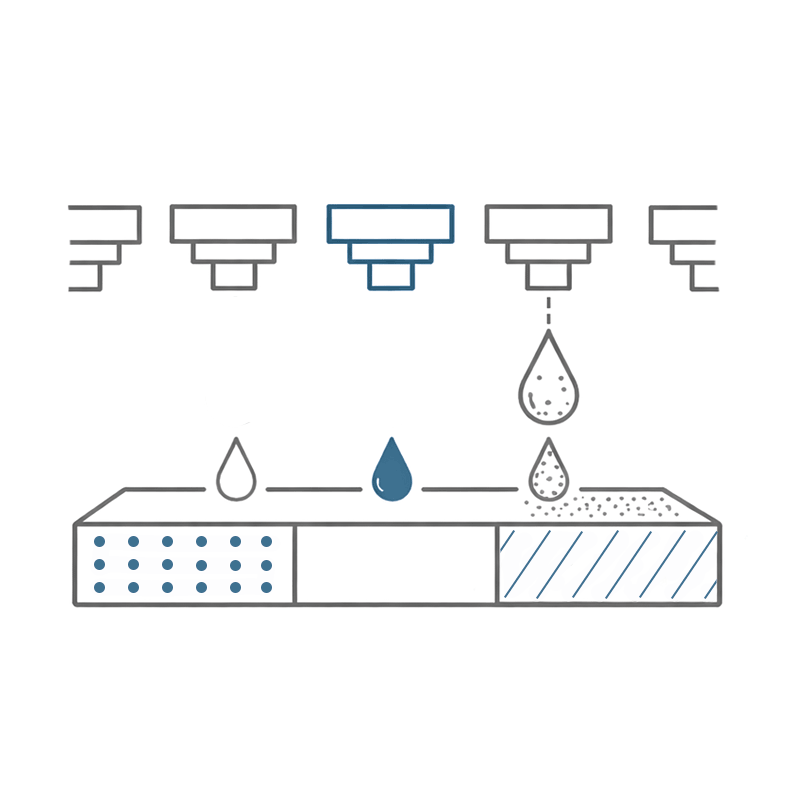

Unique Approach Multi Material Jetting

Targeted Material Deposition and Zero-Waste

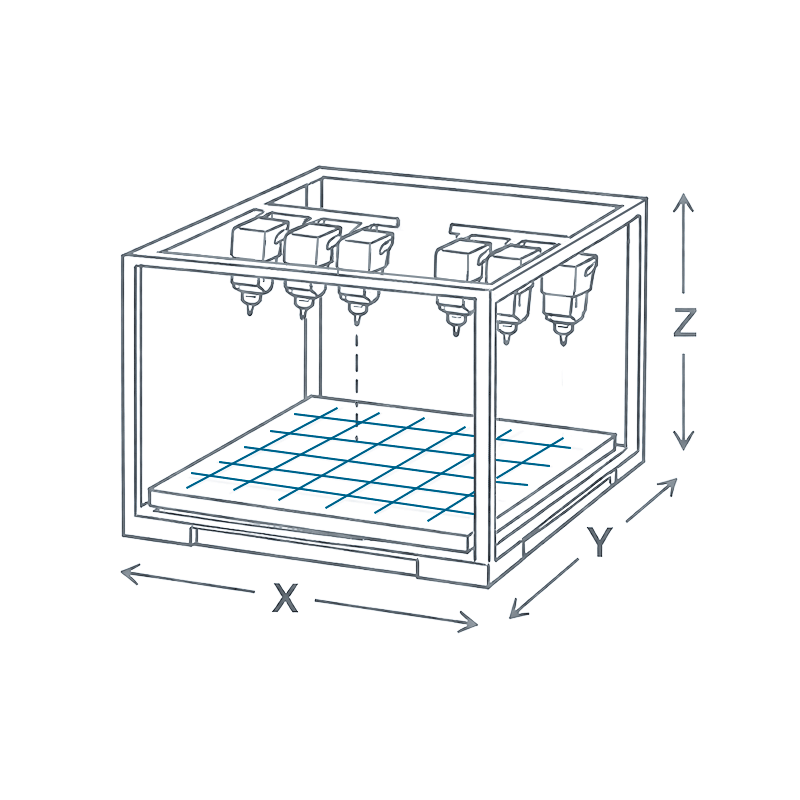

Large Build Envelope

530 x 300 x 200 mm²

Wide High-Performance Material Freedom

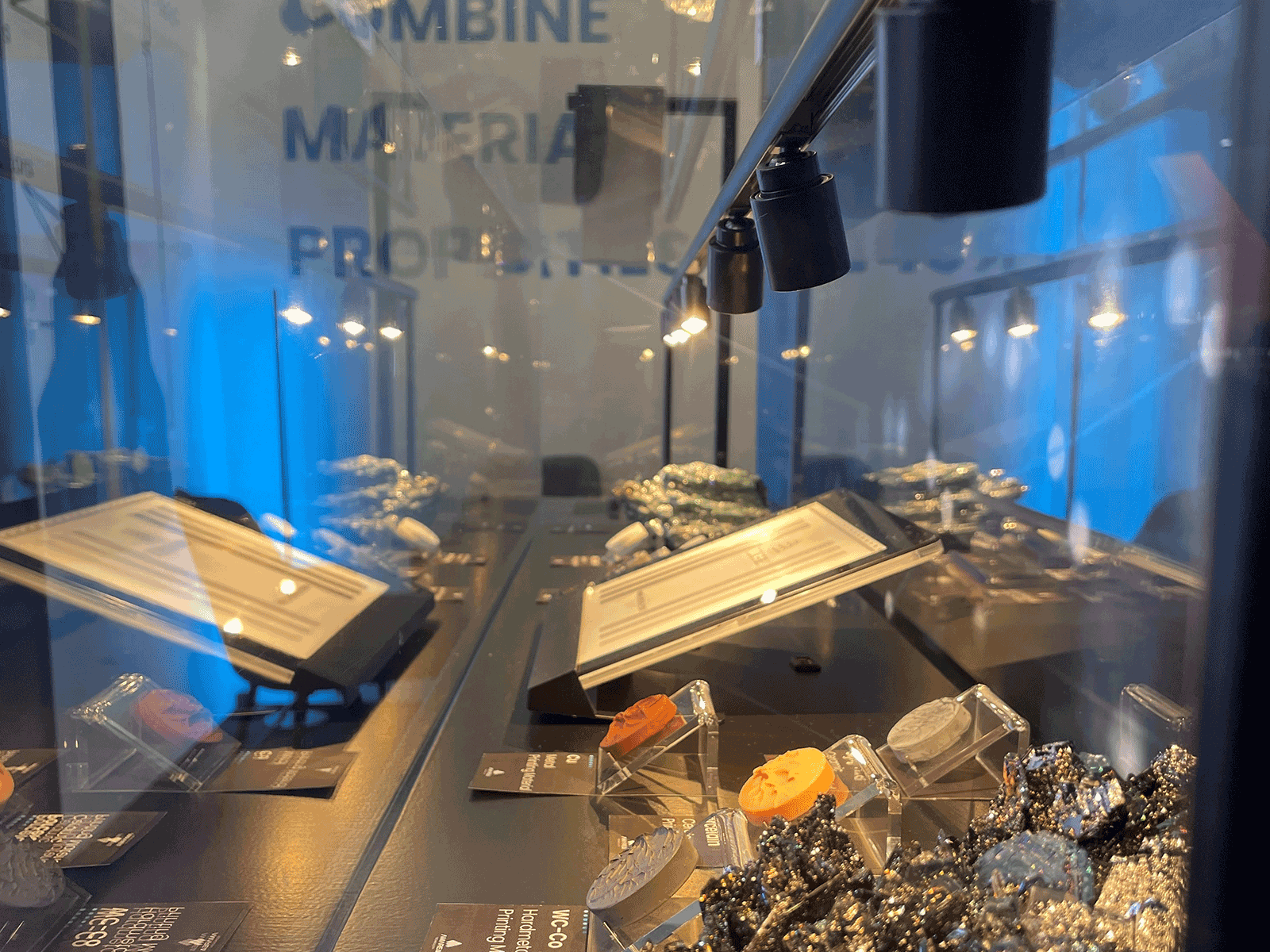

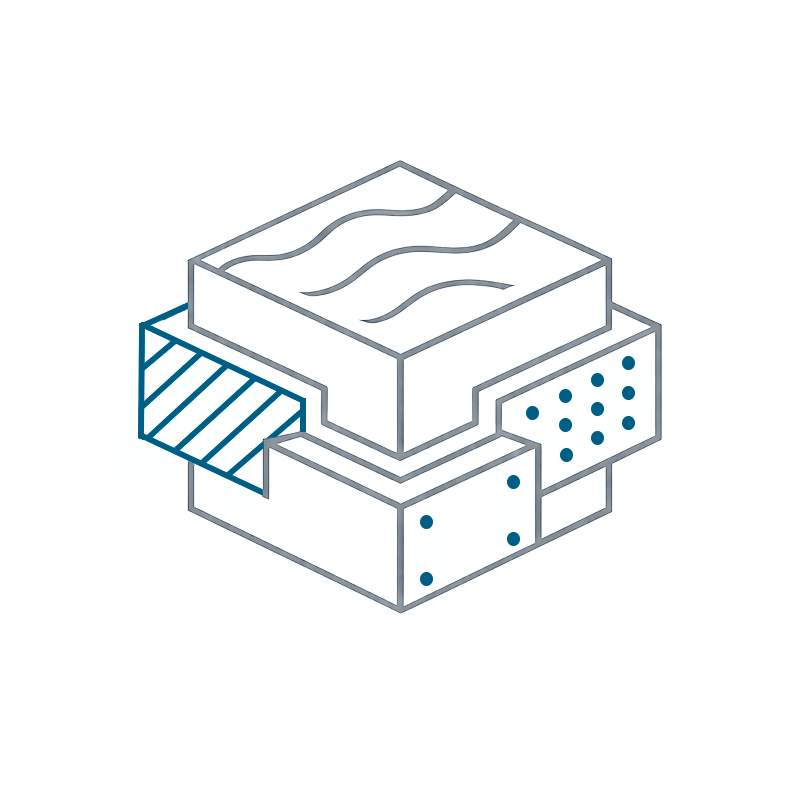

Combine Material Properties

Material properties where you need them.

- Combine up to six co-sinterable materials in one component.

- Property-driven design for electrical, thermal, mechanical use.

- Discrete or graded transitions within a single part.

- Cross-material integration: ceramics, metals, glasses, composites, etc.

- Local functionality, defined where needed, not globally.

From Assemblies to Single Parts

Functional integration instead of assemblies.

- Multiple functions integrated into one monolithic component.

- No joining required: no bonding, brazing or mechanical assembly.

- Miniaturization with higher functional density.

- Higher reliability through fewer failure points.

- Reduced process steps and manufacturing complexity.

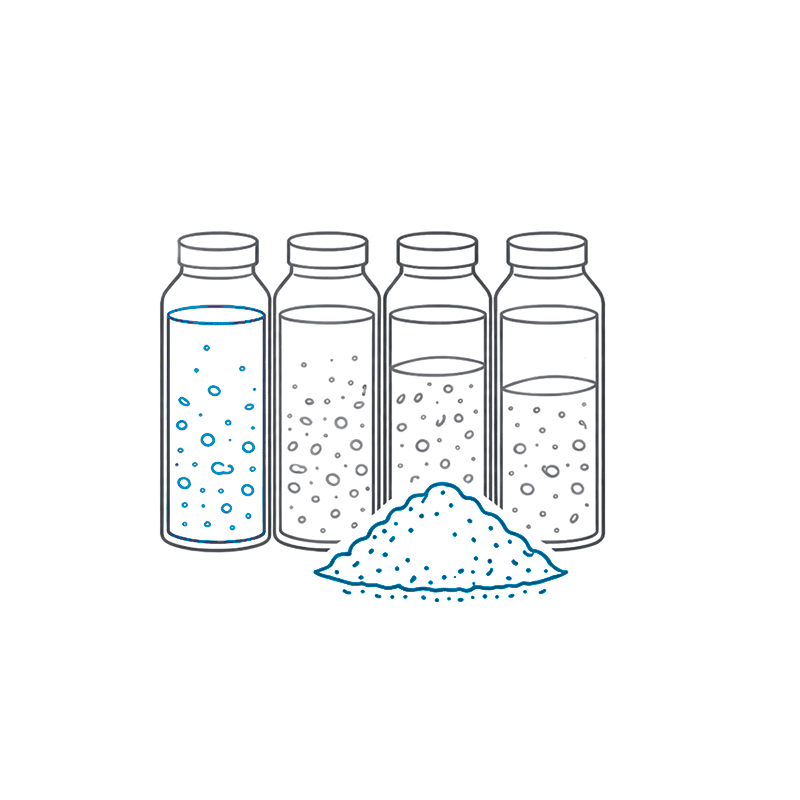

Materials Engineered for Your Needs

Established materials. New design freedom.

- Based on established powder-based manufacturing routes.

- Thermal debinding and sintering, no chemical debinding.

- High solid loading for dense, high-performance parts.

- Material-efficient deposition: material only where required.

- Long-term material stability and industrial scalability.

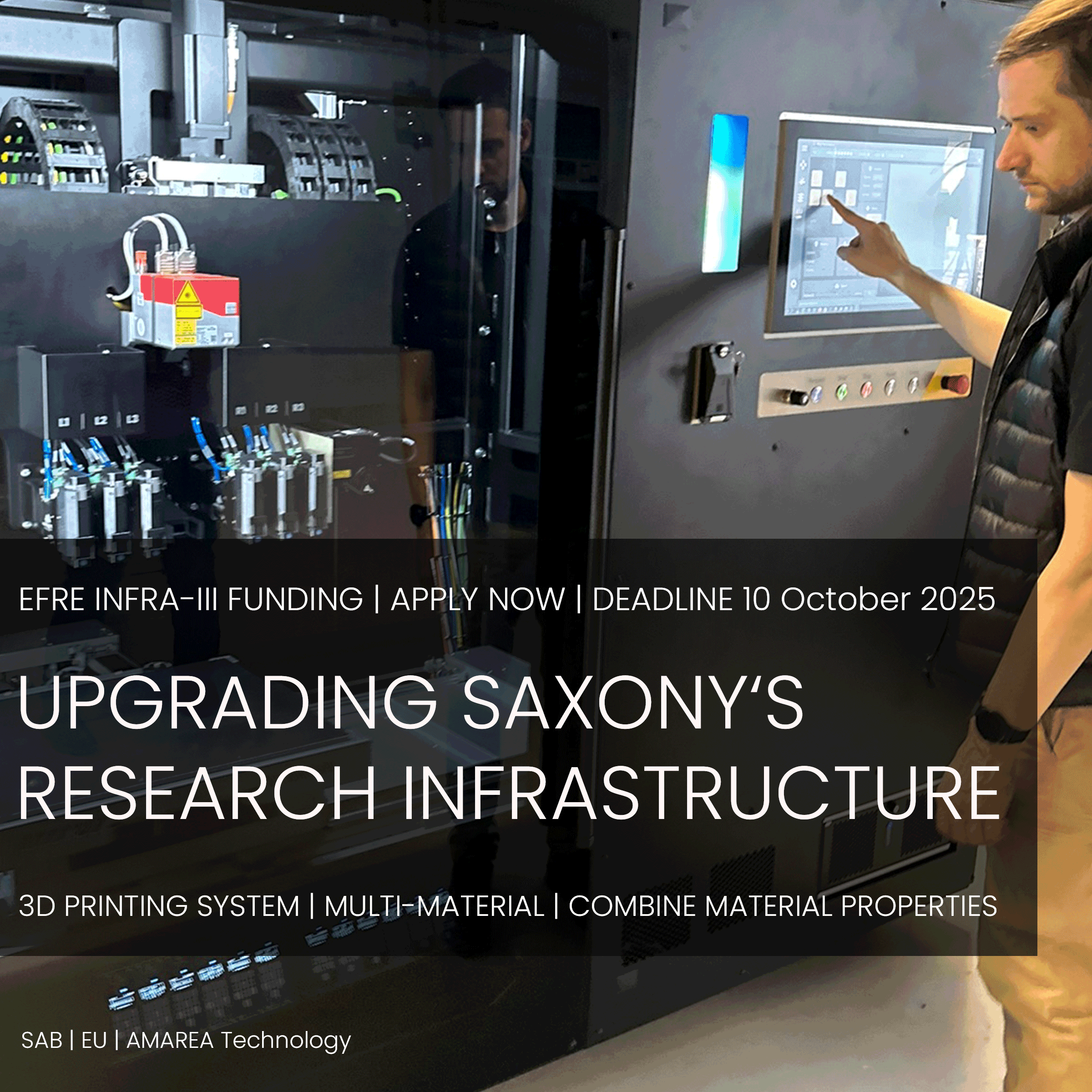

MMJ ProX Series – Enabling Multi-Material AM Technology

The MMJ ProX Series enables the precise spatial combination of different functional materials within a single component. This allows the integration of electrically conductive and insulating structures in one continuous printing process, opening entirely new application possibilities.

Showcasing an aerospace application, the MMJ ProX Series is used to integrate conductive internal pathways, electrically insulating regions, and air-cooling channels into a single component within a single printing process. The result is a fully functional, high-performance igniter designed for harsh environments.

OR GET IN TOUCH

Schedule Your Feasebility Study

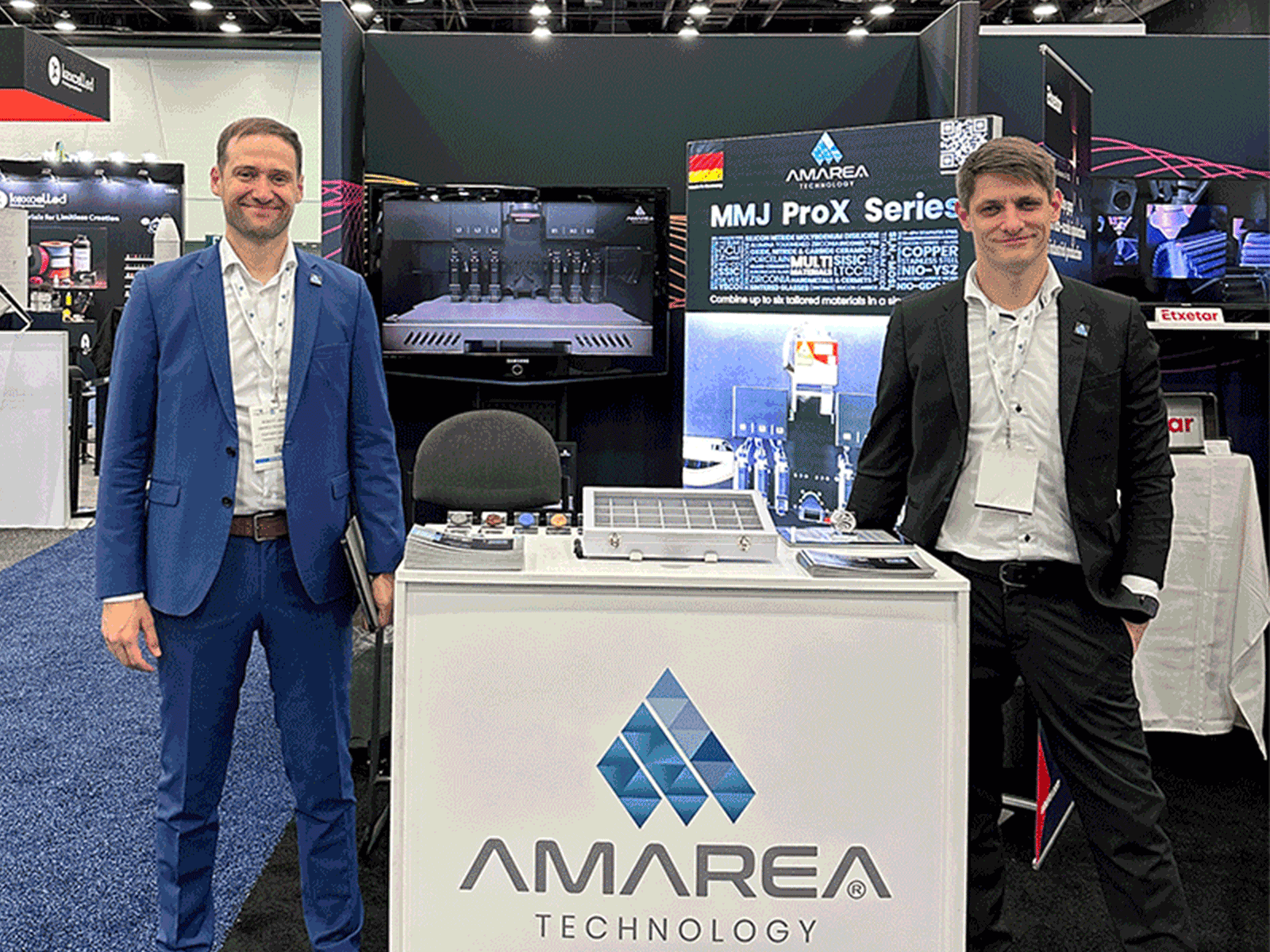

Meet us at Upcoming Events

Discuss Multi-Material Additive Manufacturing in real applications.

TCT ASIA

NECC | Shanghai, China

Hall 8.1, Booth 8H151

Duration: March 17 – 19, 2026

Ceramitec

Trade Fair Center Messe München | Munich, Germany

Hall 6, Booth 226

Duration: March 24 – 26, 2026

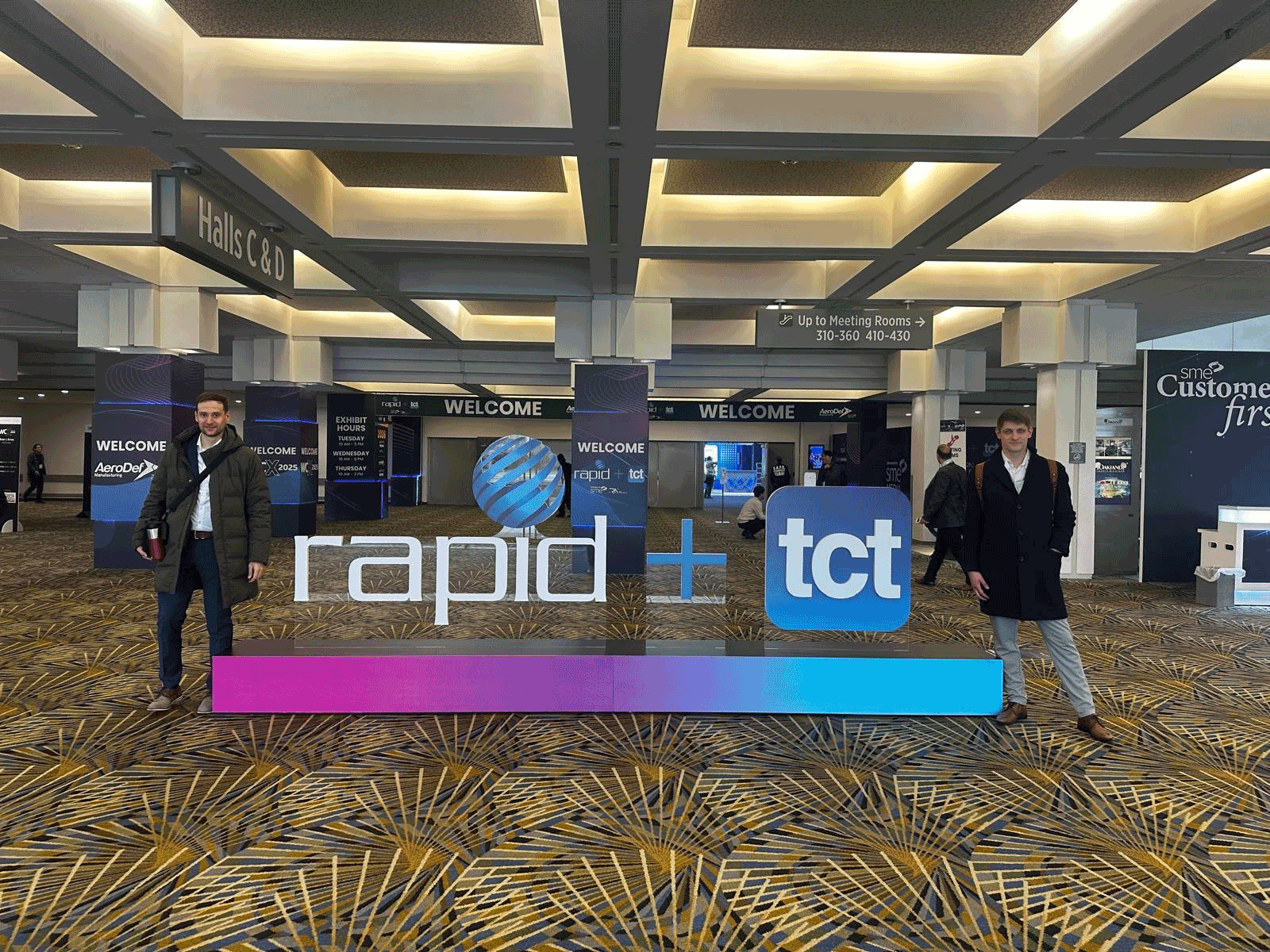

Rapid + TCT and AeroDef Manufaturing

Thomas M. Menino Convention & Exhibition Center | Boston, MA, USA

Booth 2371

Duration: Apil 14 – 16, 2026

Ceramic AM Summit

Buergerhaus Seepark | Freiburg, Germany

Duration: June 29 – July 1, 2026

Formnext

Messe Frankfurt | Frankfurt a.M., Germany

Booth tba.

Duration: November 17 – 20, 2026